1. Introduction to equipment molding process

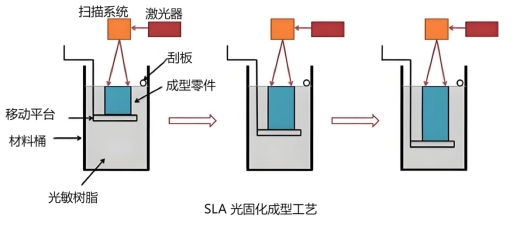

The molding principle of stereolithography is SLA (Stereo lithography Appearance), which is the stereolithography method. It is a laser curing three-dimensional printing technology that can produce solid resin parts. Related software is used to cut the three-dimensional model into layers and process the layer data, using laser When scanning the resin, polymerization occurs to solidify it, and the solid is formed by scanning layer by layer until the last layer. After printing the solid body, clean it and use a curing box for surface curing. After curing is completed, post-processing can be performed, such as sandblasting, grinding, spray painting and dyeing. The process principle is as follows:

2. Technical advantages

Ø High precision: SLA can produce very fine three-dimensional objects with high resolution and high precision.

Ø High surface quality: The surface of objects manufactured by SLA is smooth, meeting the application needs of high surface requirements.

Ø Material diversity: SLA can use a variety of photosensitive resin materials, such as transparent, black, white, etc., to meet different application needs.

Ø Rapid manufacturing: SLA can quickly manufacture three-dimensional objects, and the manufacturing speed is faster than traditional manufacturing methods.

Ø High degree of design freedom: SLA can produce very complex three-dimensional objects with a high degree of design freedom.

3. Introduction to equipment system

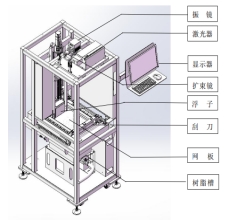

The Honor3d series of light-curing printers is mainly composed of the main frame structure, 3D printing control system, optical system and post-processing system equipment. The process is fully automatic, without manual intervention, and can basically achieve unattended production. Automatic control system, negative pressure adsorption scraper, automatic control/adjustment of liquid level, one-button start.

3.1 Equipment appearance and structure

It adopts a simple and modern industrial style white appearance design, which is elegant and beautiful. Frame-type main structure, industrial marble motion platform, stable performance.

600 equipment picture SLA600 system diagram

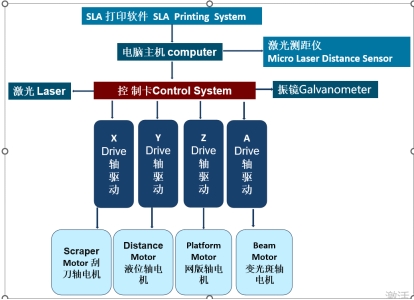

3.2 3D control system

The intelligent control method is adopted to improve the efficiency, stability and scalability of the control system.

3.3 Optical system

Stable and reliable solid-state laser, high-speed photoelectric galvanometer, quartz focusing lens. It works stably for a long time and has little attenuation.

Laser photoelectric high-speed galvanometer

4. Main parameters of equipment

Basic parameters |

model | Honor3d600 |

technology type | SLA stereolithography molding |

technology type | photosensitive resin |

Molding range | 600×600×400mm(L×W×H) |

Equipment size | 1160*1370*1900mm (excluding detachable rotating monitor stand and keyboard tray) |

Equipment weight | 800kg (including full tank of resin) |

Molding accuracy | ±0.1mm (L≤100mm); ±0.1%×Lmm (L>100mm) |

***Scan speed | 18000mm/s |

Machine tool system |

Machine tool structure | Machine tool structure Z-axis high-speed screw guide motion design concept, servo motor with brake; XY adopts frame dual-drive motion mode, marble platform to ensure long-term stable operation of the equipment, high precision and life |

base | Marble base countertop (whole cut, not spliced) |

laser system |

Laser type | Semiconductor pump source laser |

Laser wavelength | 355nm |

Laser system power | 3000MW |

Beam quality | Beam diameter <1mm, pulse stability ≤10%, power stability ≤6% |

Scan system |

Spot diameter | 0.1-0.2mm |

Focus method | F-theta plane field lens |

coating system |

Coating method | Intelligent positioning vacuum adsorption coating |

coating thickness | 0.04-0.2mm (normal: 0.1mm; precision: 0.04-0.1mm; fast: 0.1-0.2mm) |

lifting system |

Lift motor | Movement mode of screw guide rail, Lesai 400W servo brake motor |

Repeat positioning accuracy | ±0.01mm |

software environment |

operating system | 64-bit system (win10) main frequency 2.5G, memory 8G, hard disk 500G |

System software | Equipped with STL, SLC, CLI; |

System software | 3D printing system |

Data transmission method | USB /PCIE /Network port |

Resume function | Use one-click startup mode to continue playing with a traceless connection |

Support graphics operation function | Move, rotate, zoom in, copy, array, combine, and scatter. |

Liquid level out of tolerance | Support automatic suspension of liquid level over-tolerance alarm |

With deviation setting function | According to printing needs, there is a deviation setting coefficient algorithm setting function |

Operating environment |

power supply | 220VAC, 50Hz, 16A |

ambient temperature | 24~28℃ |

ambient humidity | 20%~45% |

Accessories |

User Manual | 1 set (paper file) |

cleaning tools | 1 set (stainless steel tray, blade, plastic box, brush, etc.) |

Electronic temperature and humidity meter | 1 set |

Printing system | 3D printing system (a set of dongles) |

5. Equipment configuration list

serial number | type | name | Specifications and models | Configuration instructions | quantity |

1 | host device | 3D printing equipment | JOYE600 | Standard configuration | 1 set |

2 | UV post curing box | Curing box | UV600 | Standard configuration | 1 unit |

3 | 3D printing materials | photosensitive resin | DY9111 | Standard configuration | 240kg |

4 | toolbox | Tool box box | Gloves, wrenches, blades, tweezers | Standard configuration | 1 set |

5 | User Manual | User Manual | SLA600 | Standard configuration | 1 copy |

6 | Auxiliary equipment | Dehumidifier | DR-902L | According to contract requirements/optional | 1 unit |

7 | Ultrasonic cleaning machine | 30L | According to contract requirements/optional | 1 unit |

2. Random accessories

serial number | name | Specification | quantity | unit | Brief description | Remark |

1 | Equipment pad | Rubber pad | 4 | pieces | give away |

|

2 | Cleaning box | 30L | 1 | pieces | give away |

3 | Allen wrench | Metric | 1 | set | give away |

4 | Brush (large) | 9 inches | 1 | pieces | give away |

5 | Brush (small) | 4 inches | 1 | pieces | give away |

6 | Blade | 8 inches | 1 | pieces | give away |

7 | sandpaper | / | 2 | open | give away |

8 | Dingqing gloves | / | 1 | box | give away |

9 | tweezers | / | 1 | pieces | give away |

10 | stainless steel plate | / | 2 | indivual | give away |