1. Product introduction

1. Overview

PicoStation Intelli 360 multi-modal intelligent fusion digital quality testing platform adopts large-model industrial inspection and testing technology. Through computer vision, natural language processing and 3D imaging technology, the testing platform can automatically detect product defects, predict equipment failures, optimize production processes, and generate Automated inspection reports.

The test platform mainly includes 5G communication modules, multi-modal sensing probes, robot loading and unloading, AGV automatic transportation platform, robot automatic calibration and digital quality management and tracking systems, etc., simulating the new generation of digital quality control in smart manufacturing lines. Processes and programs.

The PicoStation Intelli 360 multi-modal intelligent integrated digital quality testing platform not only enables smarter quality inspection and data analysis, but also promotes the digital transformation of the manufacturing industry. By combining with advanced technologies such as digital twins and collaborative robots, it supports real-time monitoring and optimization of production systems, provides enterprises with innovative solutions and competitive advantages, and assists the refinement and intelligent development of industrial production.

2. Working principle

The AGV automatic transport platform is used to transport the inspected parts frame to the inspection station; the grabbing robot takes the parts out of the frame and places them on the inspection platform. The manipulator will drive the multi-modal sensing probe to measure the parts. This includes the comprehensive use of white light interference probes and ultra-depth-of-field probes to measure the microscopic morphology of parts, and the use of flash probes and line laser probes to detect macroscopic shape and position tolerances of parts, and combine micro and macro multiple Modal quality data is summarized, and the multi-modal quality of parts at the same location can be viewed simultaneously on the digital quality platform. Through the 5G network, the digital quality platform can track and trace the measurement process and results, providing closed-loop feedback for intelligent manufacturing.

3. Product features

1) Automated transportation and operation: The product uses an AGV automatic transportation platform to transport the parts frame to the inspection station. The grabbing robot automatically takes the parts out of the frame and places them on the inspection platform, realizing a fully automated transportation and operation process.

2) Multi-modal sensing measurement: The product uses a variety of probes to accurately measure parts, including white light interference probes and ultra-depth-of-field probes for microscopic topography measurements, as well as flash probes and line laser probes for Macroscopic shape and position tolerance detection. This multi-modal measurement method improves the comprehensiveness and accuracy of detection.

3) Multi-modal quality data summary: The product can summarize micro and macro quality data, and simultaneously view multi-modal quality data at the same location of parts on the digital quality platform, realizing centralized management and analysis of data.

4) Digital quality platform: This platform provides tracking and tracing functions for the measurement process and results. Users can monitor the measurement situation in real time through the platform and obtain detailed measurement data and result reports.

5) Closed-loop feedback supported by 5G network: Through 5G network connection, the digital quality platform can provide closed-loop feedback for intelligent manufacturing, helping to optimize the manufacturing process and improve product quality and production efficiency.

6) High precision and automation: Through deep learning and neural network technology, large models can automatically identify and classify complex product defects, such as surface scratches, shape variations, material defects, etc. This high-precision detection capability comes from the learning and feature extraction of massive data by large models, which enables it to significantly reduce false detections and missed detections in practical applications. The automated inspection process not only improves the efficiency of the production line, but also reduces the reliance on manual inspection, reducing labor costs and the risk of human errors.

7) Real-time and adaptability: In a production environment, real-time detection capabilities are crucial. The test platform can process large amounts of data in a short time, quickly identify potential problems, and provide immediate feedback. This real-time nature ensures the continuity and efficiency of the production process. In addition, the adaptability of the measurement platform is reflected in its wide applicability to different industrial scenarios. Through transfer learning and model optimization, it can adapt to the detection needs of different materials, specifications and product types, and quickly adjust detection strategies in new environments to improve the flexibility and robustness of the system.

4. Software functions

1) Automatic loading and unloading control

Automated control equipment performs precise product picking and placement for efficient loading and unloading. Support path planning and equipment status monitoring to improve production line efficiency.

2) Multi-modal perception and data fusion

Integrate data such as macroscopic and microscopic shape and position tolerances to comprehensively analyze product status. Realize feature extraction, anomaly detection and real-time warning to improve detection accuracy. Analyze film thickness, length, width, height, angle, arc, step height, radius of curvature, line roughness and surface roughness, surface waviness, flatness, warpage, curvature, coplanarity, surface scratches, Wear, defects, volume, area.

Automated analysis function: The calculated two-dimensional morphology parameters include: skewness parameter, kurtosis parameter, ***peak height parameter, autocorrelation length parameter, texture aspect ratio parameter, texture direction parameter, root mean square slope parameter, Valley root mean square roughness parameters, surface morphology frequency spectrum density function, two-dimensional morphology parameter output and other functions. The calculated three-dimensional morphology parameters include: skewness parameter, kurtosis parameter, area material inverse ratio parameter, same area material inverse ratio parameter, maximum crest height parameter, autocorrelation length parameter, texture aspect ratio parameter, texture direction parameter, all. Root inclination parameter, unfolded interface area ratio parameter, peak material volume parameter, core material volume parameter, core space volume parameter, upper support area parameter, trough root mean square roughness parameter, expanded area parameter, projected area parameter, surface Parametric functions such as morphological frequency spectrum density function.

3) 5G automated communication and data transmission

Use 5G technology to achieve high-speed and low-latency communication between devices and support real-time data transmission. Ensure remote monitoring and control of production lines, as well as network security.

4) Large model industrial detection and intelligent analysis

Use AI large models to detect product defects and intelligently analyze them, and automatically identify and classify them. Implement predictive maintenance and provide production optimization and decision support.

5. Product parameters

Multimodal sensing probe

1) Three working modes to choose from: white light interference measurement mode, stepless zoom measurement mode, and film thickness measurement mode;

2) White light interference measurement mode: suitable for smooth surfaces and ultra-high-precision measurement scenarios;

3) Super depth of field measurement mode, suitable for measurement of large roughness, large slope, curved surface and groove profile;

4) Reflection spectrum film thickness measurement mode, suitable for nanoscale film thickness measurement;

5) Interference objective lens: 10X (other models optional);

6) Customized white LED light source, high brightness and long life. Provide monochromatic LED light source options;

7) Z-direction measurement range: 100μm range in piezoelectric mode, 1nm-10mm range in vertical scanning mode, using patented vertical scanning method to support output of high-precision measurement data in large-range scenarios;

8) Z-direction anti-collision: software anti-collision ZSTOP setting, hardware anti-collision sensor;

9) Automation functions: automatic measurement/automatic multi-area measurement/automatic splicing measurement;

10) Automatic analysis: one-click analysis/multiple file analysis;

Manipulator

The load is 5kg, the arm span is 1008mm, and the maximum working radius is 886.5mm. It has a wide range of applications and rich configurations. Each joint can achieve ±360° rotation.

AGV mobile platform

1) Load: ≥60kg;

2) Driving mode: two-wheel differential drive;

3) Communication interface: standard CAN RS232;

4) Climbing angle: ≤8°;

5) Secondary development function: Provide open source SDK, ROS-PACKAGE, and support secondary development;

6) Obstacle avoidance: step 10mm, gap: 20mm;

High performance dimensional measurement platform

1) Image sensor: 5 million pixel CMOS

2) Lighting system: epi-illumination system: four-divided illumination (white light), transmission system: telecentric illumination (green)

3) Field of view: 200×200mm

4) Repeatability: 1μm/±2μm

5) Measurement accuracy: without splicing: ±2μm, with splicing: ±(4+0.02L)μm

6) Display resolution: 0.1μm

7) X movement range: 110mm/210mm, coordinate table load-bearing 5kg

8) Z-direction movement range: 35mm/75mm (electric)

Digital quality management platform

1) Contains the visual operation interface of the k8s system. Its functions mainly include sub-node task scheduling, resource occupancy, sub-node task progress, etc., and is accompanied by instructions or technical guides;

2) You can use the GPU to train and run deep learning models through the docker (installation 19.03) container, which is compatible with pytorch, TensorFlow, transformer and other frameworks;

3) Data interaction operations can be performed between the master node and the child nodes. The data sets, labels, and training results required for deep learning can be stored in the cloud (or local storage). The relevant data can be output and called through the exposed port, that is, k8s can be accessed externally. Information within the system;

4) The number of child nodes can be expanded and expansion is supported as needed.

6. Equipment configuration

1 | Multimodal sensing probe | PicoStation | 1 |

2 | Manipulator | - | 1 |

3 | AGV mobile platform | -- | 1 |

4 | High performance dimensional measurement platform | - | 1 |

5 | Digital quality analysis software | Including calculations of step height, roughness, etc. | 1 |

6 | brand computer | Lenovo | 1 |

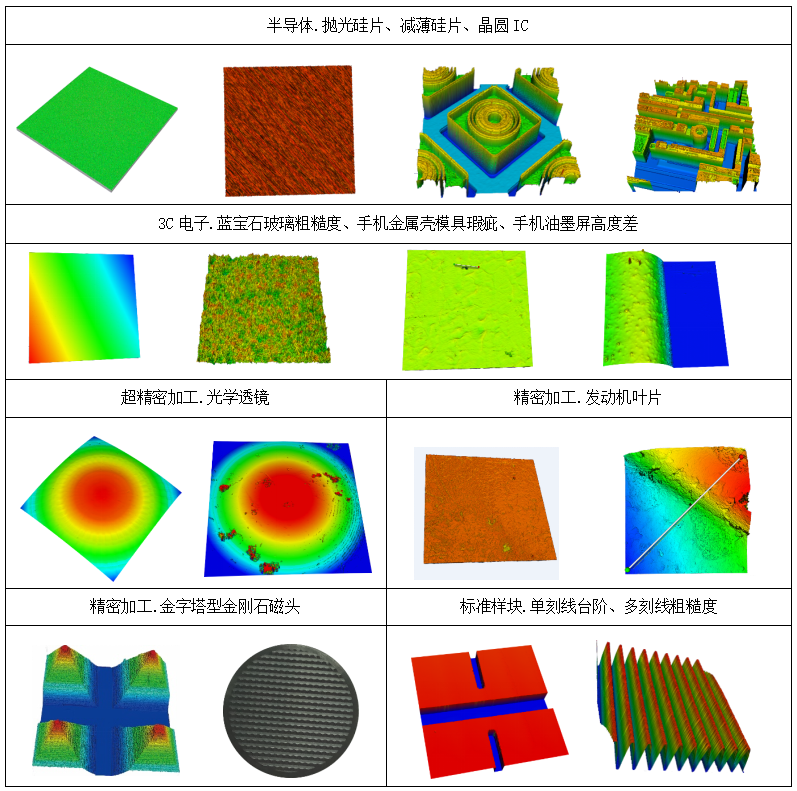

2. Application fields

Conduct surface morphology characteristics such as flatness, roughness, waviness, surface contour, surface defects, wear, corrosion, pore gaps, step height, bending deformation, and processing conditions of various products, components, and materials. Measurement and analysis.