X-ray three-dimensional dimension measurement system (abbreviated as industrial CT) is a measurement equipment that organically combines computer technology with radiology and uses tomography technology or tomography imaging technology to achieve three-dimensional imaging of the measured object. It can achieve three-dimensional microscopic imaging and internal size analysis and detection of objects without destroying the internal structure of the object. Compared with conventional measurement methods, it has higher measurement accuracy, is not affected by the optical properties of the sample surface, and has no dead ends in detection. High detection efficiency and other advantages. Widely used in aviation, military, metallurgy, machinery, petroleum, electric power, geology, archaeology, materials, etc.

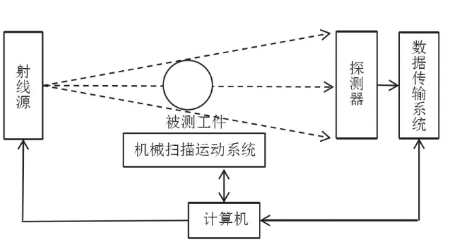

Industrial CT Principle and Structure

Industrial CT technology is a technology in which projection data obtained after X-rays penetrate an object are processed by computers using corresponding mathematical methods to reconstruct a two-dimensional image on a specific level of the object, and a three-dimensional image is formed based on the reconstructed two-dimensional image. During the process of X-ray penetrating an object, it is affected by the material, density and shape of the object and produces varying degrees of attenuation, causing a large change in the X-ray intensity after penetration, thereby showing the internal structure of the object being detected.

Industrial CT structure

System composition

As shown in the figure, the industrial CT system mainly includes components such as a radiation source, a mechanical scanning motion system, a detector, a data transmission system, and a computer system (hardware and software). The ray source can produce X-rays and is generally used for the detection of materials with higher density. The detector mainly collects X-rays. Detect the charge, collect data on the charge, and the performance of the detector determines the quality of the tomographic image. The mechanical scanning system is a structure that completes three-dimensional movement during the scanning process, and its rotation is controlled by the computer system. The computer system mainly processes and processes images to obtain the required shape and size data.

Equipment introduction

Technical parameters | METROTOM 1 |

Installation area | 1.74 mx0.87 m (excluding PC) |

X-ray tube | 160kV, 600W |

voxel size | 65 μm |

detector | 2560x2560(2,5k) |

Accuracy | MPE(SD) 5um+L/100 |

Minimum height from ceiling | 2.20m |

Recommended height from ceiling | 2.50m |

front space required | At least 1.5m |

Required space on left and right sides | At least 0.85m |

Space required at the rear | At least 0.1m |

Machine weight | About 2100kg is evenly distributed at four support points |

Each support point carries | About 575kg |

support point | 4xφ80mm |

Three-phase power supply | 220-484V adjustable |

power | 6 kVA |

Energy consumption | 4kwh |

Application introduction

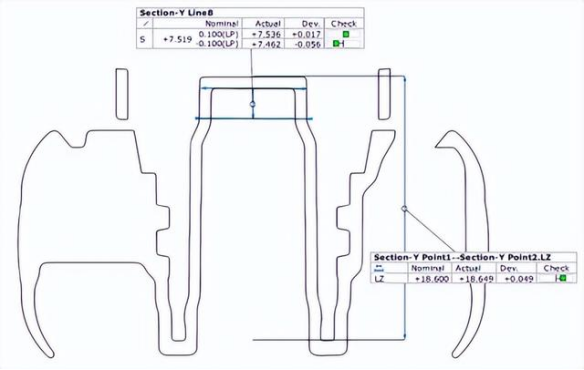

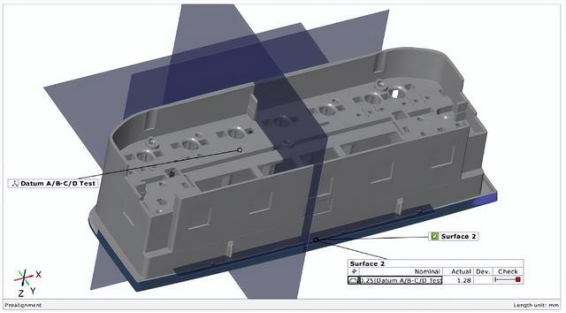

The equipped GOM Volume Inspect software features innovative 3D volume rendering and 3D visualization of all sections.

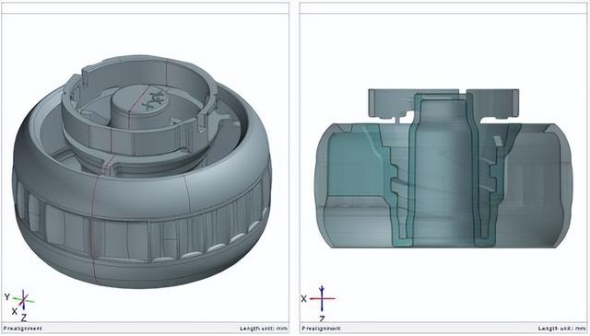

Bottle cap cross-section analysis and detection

Bottle cap distance check

With GOM Volume Inspect software, you can gain insight into parts and analyze geometry, pores or internal structures, and assembly conditions.

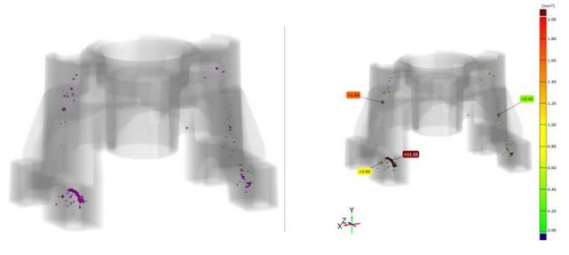

Light metal porosity detection and assessment

Efficient and accurate presentation

A one-stop scanning solution that provides comprehensive details of the entire part. Measure hidden or internal feature dimensions and internal defects, and conduct qualitative and quantitative analysis of defects according to industry standards.

Medical rubber and plastic shape inspection

Make the most of the measurement volume, scan multiple parts in batches, and automatically split and inspect them.

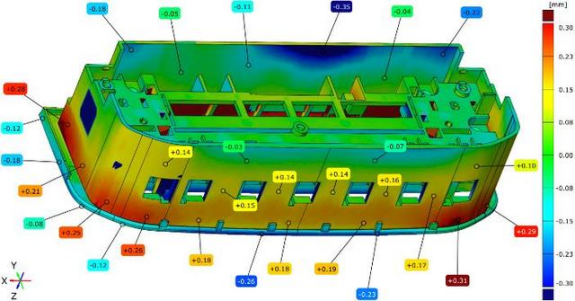

Inspection of complex automotive rubber and plastic parts

Comparative deviation detection of complex automotive rubber and plastic components